3D printing, known as additive manufacturing, is a relatively new, quickly growing method with numerous applications in healthcare, especially dentistry.

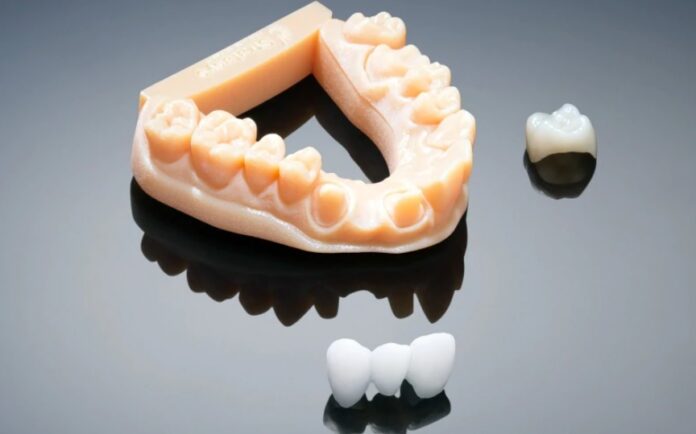

With the rising production of 3D models with 3D printers using CAD/CAM or 3D scanners, it is now possible to produce the desired complex and precise geometry 3D replicas, crowns, bridges, copings, and abutments, which were very difficult to furnish with conventional techniques.

3D printing helps to easily produce complex geometry dental implants and surgery guides or drill guides. 3D printers also print bone tissue favoring the patient’s requirements that can act as a biomimetic scaffold in the mouth for bone cell enhancement, tissue growth, and differentiation.

3D-printed bone implants can replace the deficient part using biocompatible materials like PEEK (polyetheretherketone). The integrity of the implant is important in minimizing the stress transfer to the 3D printing and is capable of producing implants with bone-like morphology to reduce the stress induced on the bone.

In addition, 3D imaging plays an important role in the diagnosis and treatment planning of dental diseases. Transforming digital images into real objects that can be felt and touched will provide new opportunities to practitioners regarding operative skills, patient communication, and treatment planning. It could also serve as a teaching model for dental students’ skill training.

3D printing in prosthodontics

Custom trays can be manufactured or 3D printed from computerized scans of impressions or models. Model printing directly from intraoral scan helps quick fabrication of prosthesis. In RPD, the resin framework can be tried in a patient’s mouth before casting. In fixed and removable prosthodontics, restorations could be designed using CAD software, and crowns, bridges, copings, abutments, etc., can be printed using 3D printers. Printing of coping or full contour resin patterns can avoid the process of making manual wax patterns, followed by which the consequences of wax distortion can also be minimized.

3D printing in surgery

The development of 3D imaging has enabled us to attain a more precise diagnosis and improved treatment planning. 3D models of detailed replicas of the skull and jaws of patients serve as anatomical models, which have been beneficial in presurgical planning and as a reference during surgery.

Surgical guides, augmentation of bone defects, and creating replicas of jaws that could serve as study models for students, fixation plates, etc., can be 3D printed and used for Oral and Maxillofacial and Orthognathic surgeries. The absent parts of the external ear caused due to birth defects or disorders, when tried to restore, demand a very clear understanding of the complex anatomy. 3D printing could serve the purpose.

3D printing in endodontics

3D printing serves as a solution for endodontic challenges; some of which include guided access with pulp canal application in autotransplantation, accurately locating the osteotomy perforation sites, presurgical planning, educational models, and stent guides

3D printing in orthodontics

Indirect bracket-bonding splints, occlusal splints, aligners, etc., can be 3D printed. Adjustment or customization in terms of angulation, bending, etc., is possible during the manufacture of brackets. In addition, it is now virtually possible to present the changes the braces will cause in advance.

Advantages of 3D printing

When 3D printed restorations are compared with conventionally made ones, their high-quality precision, accuracy, detail recording capacity, and finely finished restorations make 3D printing technology the winner among all other available processing methods in dentistry. Its higher efficiency, resolution, flexibility, ease and quick fabrication, lesser material wastage due to additive procedures, and superior diagnostic and learning abilities stand for the importance of 3D printing in dentistry.

Disadvantages of 3D printing

3D printing is a costly technology. The techniques involved in 3D printing have disadvantages of skin irritation, mess, inflammation due to contact and inhalation of powders, the requirement of support materials, etc. Ceramics, one of the widely used materials in dentistry, cannot be 3D printed due to high porosity caused during fabrication. With furthermore research and the employment of improved techniques in the upcoming years, the disadvantages of 3D printing could be corrected.

3D printing technology can revolutionize dentistry. It has a high potential to serve as an educational tool. The ultimate goal in dental practice is to provide the most technologically advanced dental treatment to patients with high accuracy and the least discomfort. Innovations like 3D printing help create the most accurate models and provide extended learning opportunities for better treatment care to patients. The advantages of 3D printing technology outweigh the disadvantages. Overall, 3D printing technology has tremendous potential to transform dentistry’s education, research, and treatment care.

![Best hospitals for robotic surgery in India [Updated]](https://roboticsbiz.com/wp-content/uploads/2019/12/surgical-218x150.jpg)